Packaging Line Automation Solutions - Leading Packaging Equipment Manufacturer

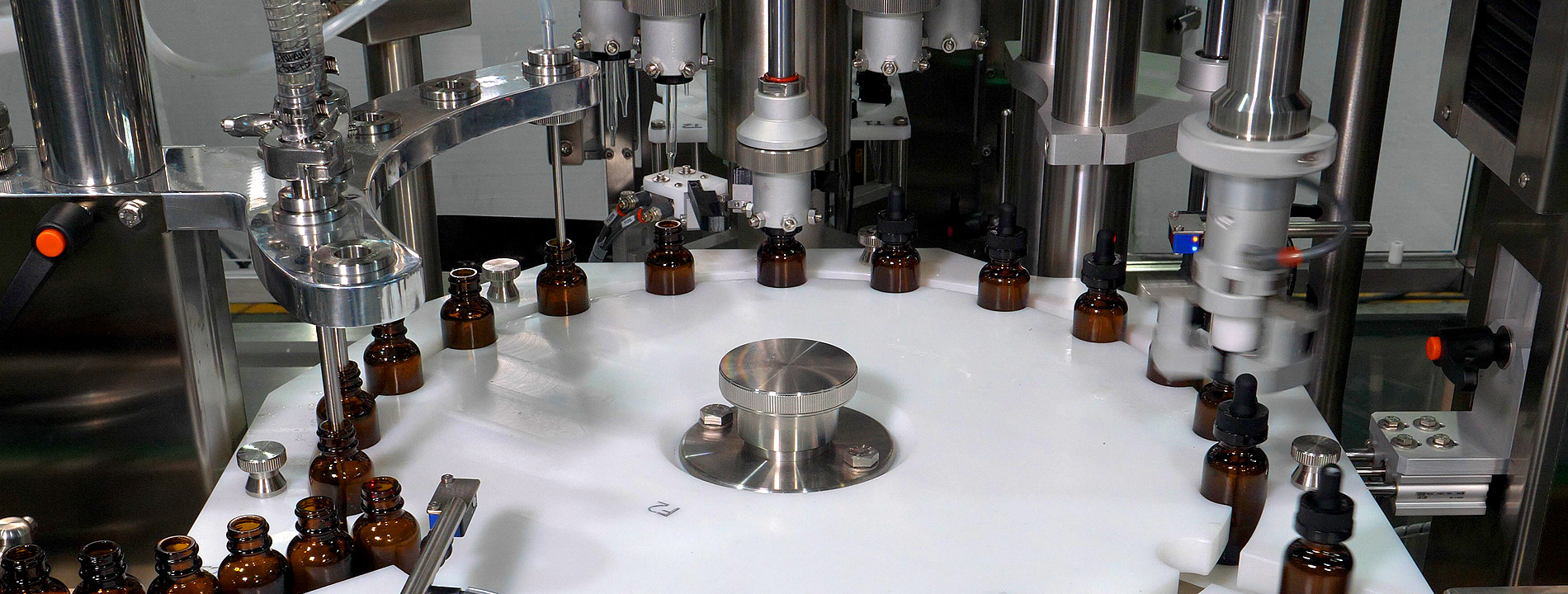

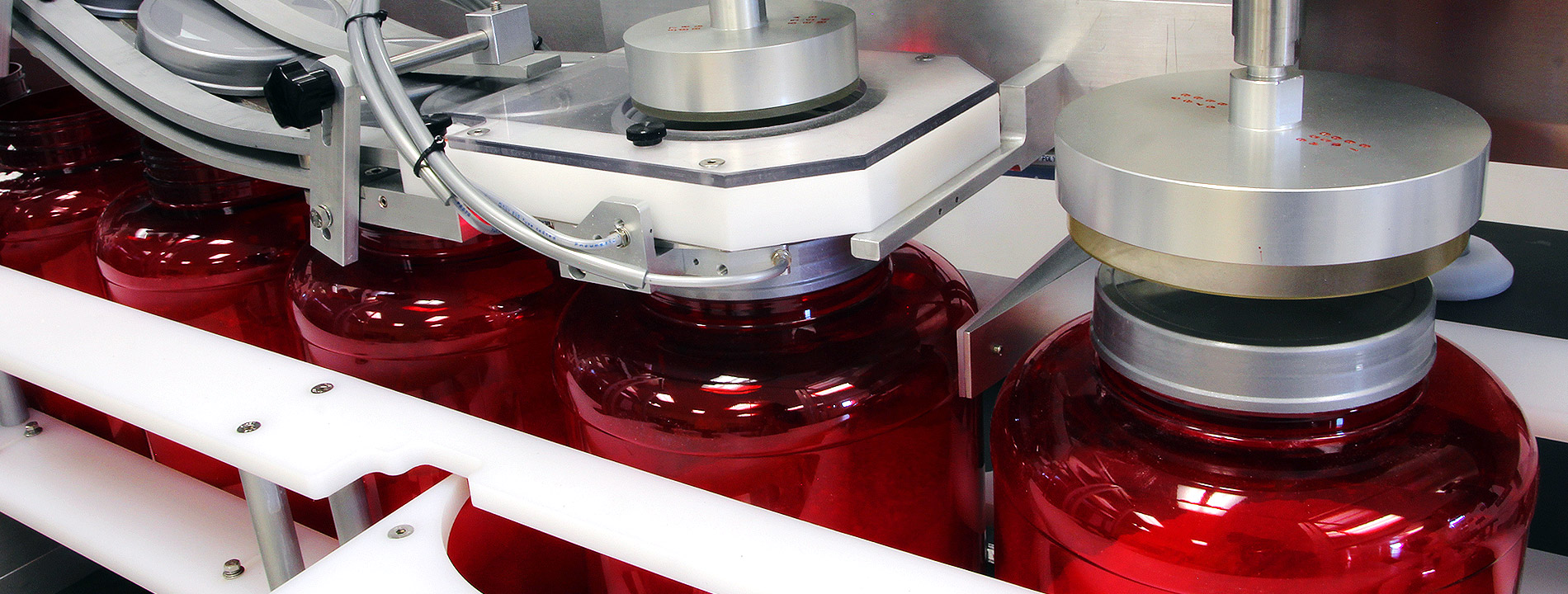

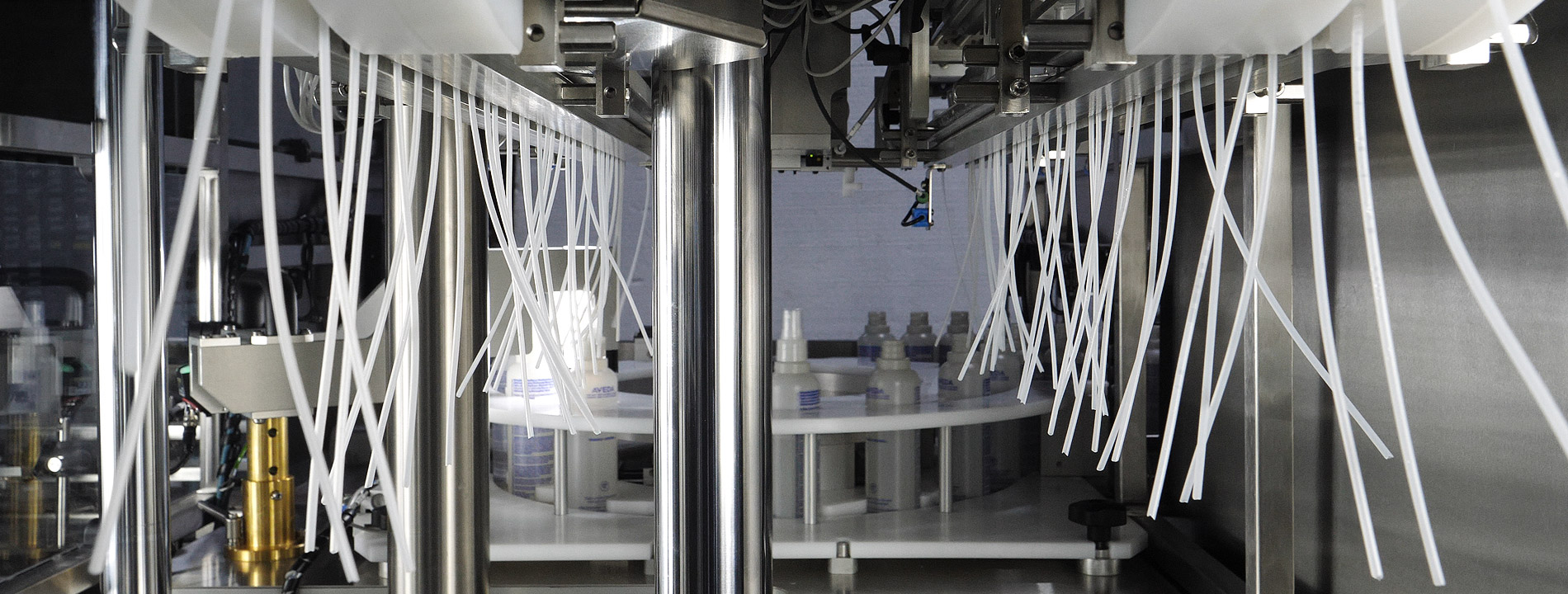

BellatRx is a leading packaging equipment manufacturer of complete packaging lines and packaging machines and your number one source for innovative, advanced, and automated packaging and filling solutions. Our expertise lies in the engineering and manufacturing of innovative equipment designed to your specification for a turnkey operation. We create and manufacture liquid filling machines and monoblocs, solid-dose filling machines, cappers and torquers, labelers, bottle unscramblers, banding and sleeving machines, conveyors, and accumulation and recovery systems focusing on Rigid Containers.

Featured Packaging Equipment Videos

We have built up a library of over 150 videos online and keep adding new ones regularly with unique solutions to customer requests.

Need more information or don’t see what you are looking for? Feel free to contact us anytime.

Packaging Industries

BellatRx is a leading manufacturer of primary packaging lines and packaging equipment serving a broad range of industries.

About Our Packaging Company

BellatRx strives to achieve a first-in-mind, best-in-class position in the packaging industry by going beyond your expectations.